Powering Possibilities with State-of-the-Art Facilities .

Powering Possibilities with State-of-the-Art Facilities;

At ECI Systems, our state-of-the-art infrastructure is designed to support innovation, precision engineering, and large-scale industrial automation projects. Our facilities are equipped with cutting-edge technology, ensuring seamless design, manufacturing, testing, and training operations to meet the evolving demands of both domestic and international markets.

Home to our design and development team, driving innovation and customized automation solutions.

A centralized, fully-equipped unit delivering comprehensive system engineering solutions for large-scale projects across various industries.

A dedicated panel shop for electrical, control, and instrumentation panel manufacturing, along with a fully integrated testing centre for conducting Factory Acceptance Tests (FATs).

A state-of-the-art 15,000 sq. ft. facility featuring a 10-zone DIP pre-treatment system and two advanced powder coating booths, ensuring superior finish, durability, and precision in coating applications.

A specialized service-oriented training facility, focused on technology upgrades, life cycle business support, and skill development to ensure global competency.

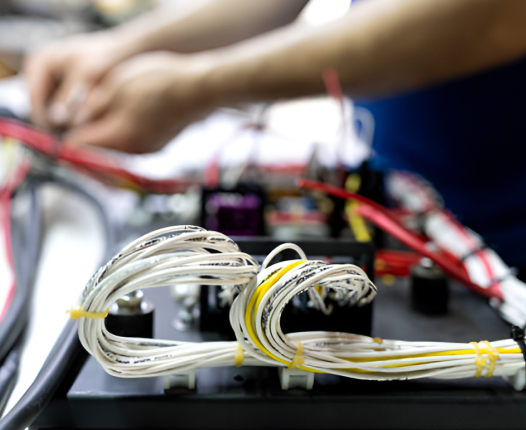

Equipped with state-of-the-art machinery, ensuring high-quality wiring solutions and precision assembly.

At ECI Systems, quality drives every aspect of our manufacturing, automation, and service delivery. Our ISO 9001:2015 certified by Bureau Veritas, UL/CSA508A certified by UL Solutions and IEC 61439, accreditations reflect our stringent adherence to international quality norms, ensuring that every solution we provide meets the highest standards of reliability, safety, and efficiency.

Our systems are audited and certified by Bureau Veritas, surpassing even the most stringent international norms.

Our expertise in automation solutions spans the entire production lifecycle, ensuring end-to-end performance and durability.

Through our experience in systems engineering and manufacturing methodologies, we refine and enhance our automation solutions to deliver consistent value to our clients.

To maintain engineering excellence and process optimization, we adhere to globally accepted quality and reliability frameworks, including:

A systematic approach to identifying potential failures in components and subsystems, allowing for proactive risk mitigation.

A structured validation process ensuring that all engineering design and specification requirements are met consistently in mass production.

A data-driven methodology that enables us to analyze, resolve, and prevent complex issues, ensuring continuous quality improvement.

Every automation system, control panel, and industrial solution undergoes rigorous quality testing before deployment.

Our approach integrates advanced automation technologies, ensuring efficiency, precision, and sustainability.

We collaborate with our clients to align our solutions with their operational goals, ensuring seamless integration and long-term reliability.